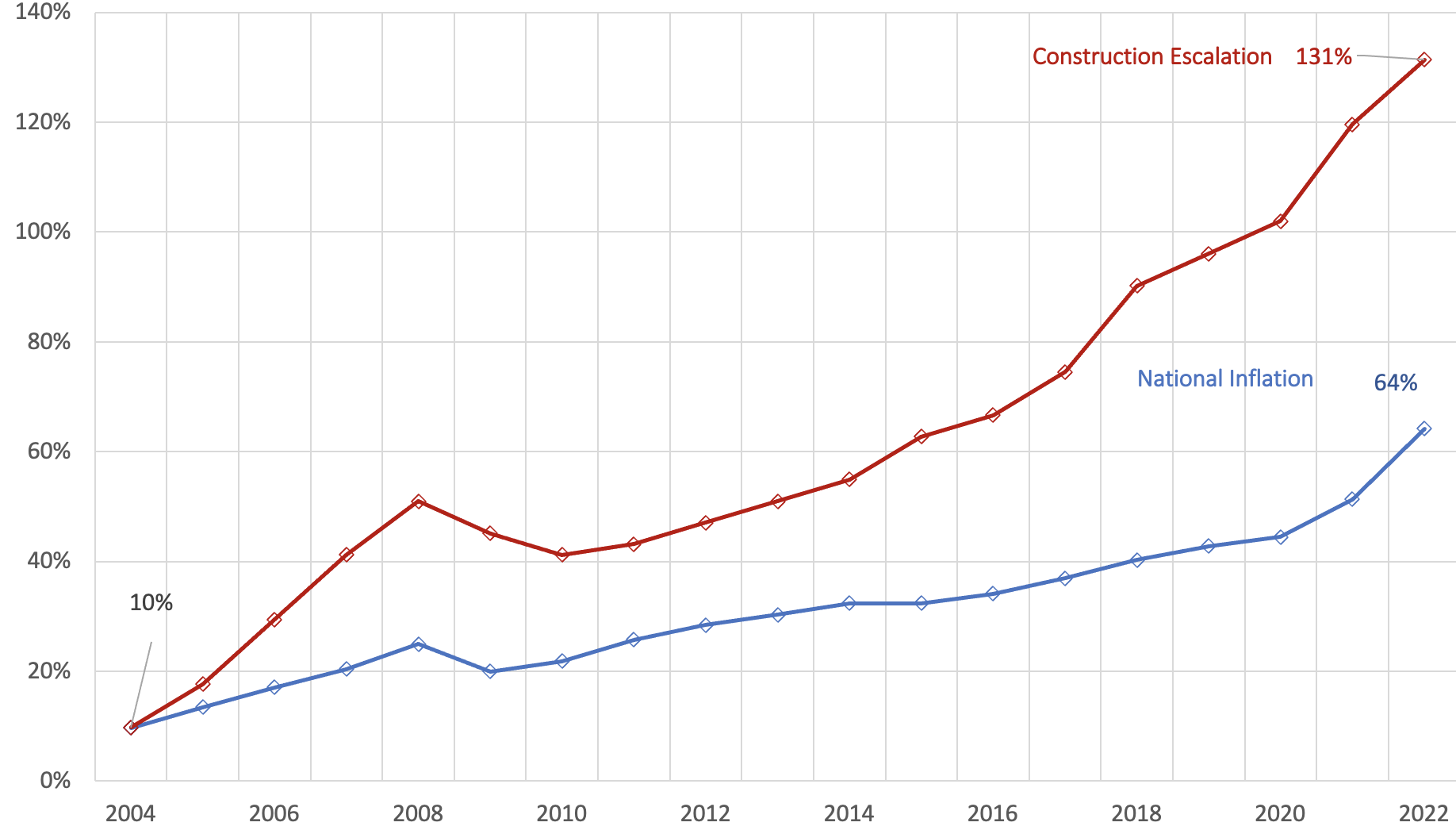

Construction costs continue to grow at a far greater rate than the rest of the economy, as shown below. The excessive costs are cause by high instability and risk; by fragmentation and decades-old processes; and by mis-alligned compensation structures.

Building CATALYST provides the data and computing platform to solve all of these problems. It begins with a proven knowledge system that stablizes planning, budgeting, and cost managment. Then, CATALYST lets owners, designers and builders experience first hand how our data/tech and processes can be integrated and automated. Finally, CATALYST provides impartial valuation of building scope and costs. This enables measurable process improvement against objective standards - which is the key re-aligning compensation to reward reduction in waste (time and cost),

Building CATALYST provides an important first step toward a larger vision - to apply industrialized construction mehtods to reduce time and cost, and make the process more enjoyable and rewarding. This is attained by using the Deming Win-Win management philosophy that transformed manufacturing following World War II.

If you are interested in getting started with Bulding Catalyst, please contact us at: Info@buildingcatalyst.com

End Note (1): Construction escalation is based on Construction Analytics data research. See edzarenski.com. National Inflation is based on US Inflation Calculator.